GALVA DÉVELOPPEMENT

LABORATORY EQUIPMENT

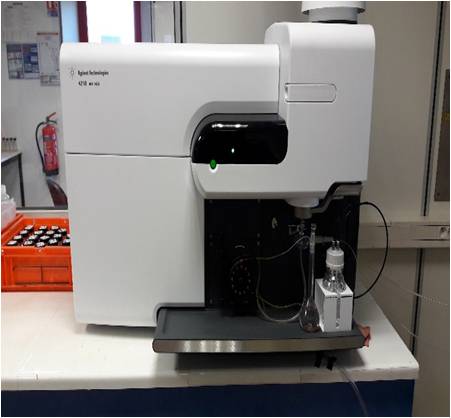

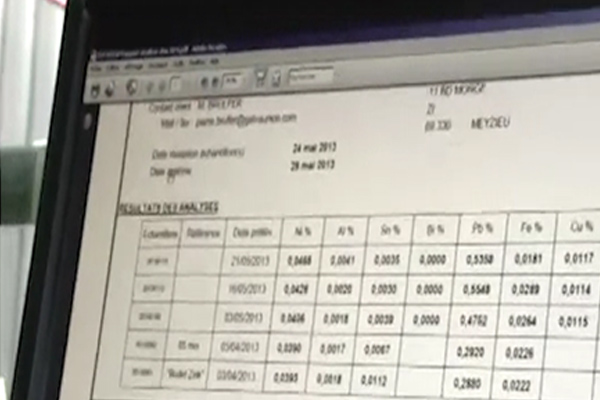

Microwave plasma optical emission spectrometer

The spectrometer is able to analyse a large number of metallic elements:

- Aluminum, calcium, magnesium, phosphorus, potassium, silicon, sodium, titanium

- Bismuth, chromium, copper, tin, iron, manganese, nickel, lead, vanadium, zinc

Applicable to galvanizing and surface treatment baths (galvanizing, electrolysis, etc.), on steels and zinc alloys, and on the environment: rainwater and groundwater.

- Average delivery time: 5 to 10 working days depending on the complexity of the material to be analysed

Possibility of analysing other metallic elements with a delay of 2 weeks to 1 month depending on the complexity of the method to be developed.

Automatic titrator

The automatic titrator is equipped with a sample changer and coupled to a distiller.

It analyses the concentrations of HCl, NaOH, Cl-, NH3 (with distiller) and measures the pH.

Applicable to all surface treatment baths (galvanizing, electrolysis, etc.) and to the environment: rainwater and groundwater.

- Average delivery time: 5 to 10 working days depending on the nature and quantity of samples to be analysed

Possibility of developing other analysis (about 3 to 6 weeks of development method depending on the complexity).

Additional services

Traction test

- Wire breaking test

- Average completion time = 8 working days

Environment

- Total hydrocarbon content (HCT) of rainwater or groundwater

- Expertise of pollutants in a rainwater or rainwater treatment plant

- Average completion time: to be negotiated according to demand (subcontracted analyzes)

Jobsite expertise

- Determination of the lead content in dust taken from a construction site (samples with wipes)

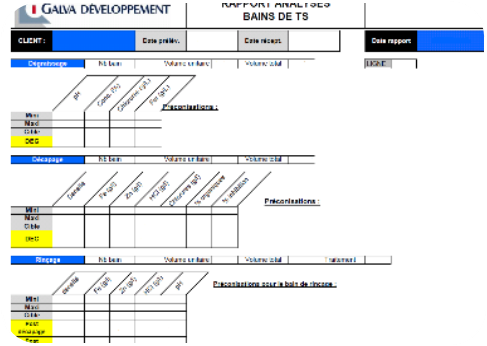

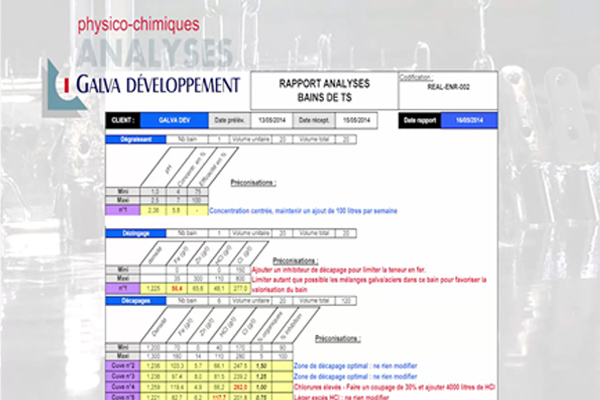

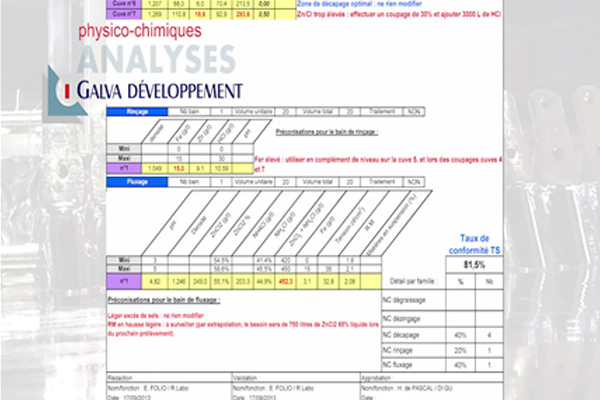

Reports

- detailed

- customized

- graphic

Pilot line

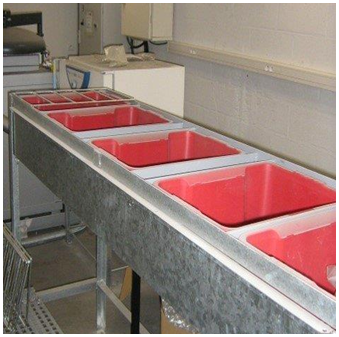

The pilot line represents the miniaturized ISO 1461 galvanizing process installed in the laboratory. It can be dedicated to experimental and solution campaigns for surface treatment.

The pilot line includes 5 surface preparation tanks (5x24L) of which 2 are heated: degreasing, pickling, fluxing and 2 rinses. It is also equipped with an oven. The electric oven is equipped with a 30L ceramic crucible. This contains molten zinc at 450 ° C (max temperature 1100 ° C)

The line allows you to:

- Test different parameters of preparation baths to optimize existing processes

- Test and compare different products on the market

- Test new surface preparation products

- Test zinc alloys

Pilot line

Kettle

Applications

Collector

Analyse

Recommend

GALVA DEVELOPPEMENT

Contact

- Laboratory Manager

Eric FOLIO

Tel : +33 238 344 355

Address

- 17 Rue de la Gare

Zone Industrielle

45300 ESCRENNES - Tel : +33 238 340 091

- Fax : +33 238 340 562

- Email :galvadeveloppement@galvaunion.com

CHOOSE A PLANT