Galvanization Process

DEFINITION OF THE PROCESS

The ISO 1461 hot dip galvanizing process consists of immersing steel parts in a molten zinc bath (approximately 450 ° C) to produce a protective anti-corrosion coating on the steel.

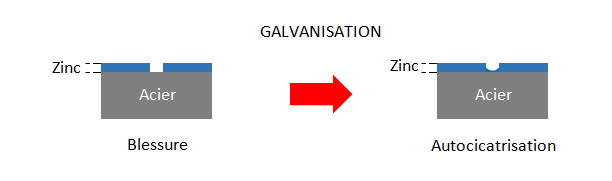

ISO 1461 hot dip galvanizing provides both screen protection (zinc on the surface protects the metal it covers) and sacrificial protection (zinc sacrifices itself to protect steel).

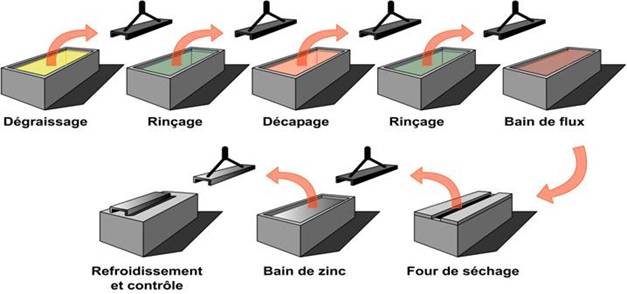

The galvanizing process is based on several steps.

STEPS IN THE HOT GALVANIZATION PROCESS ISO 1461

- Surface preparation before immersion of the parts in the zinc bath. It includes degreasing, stripping, rinsing, fluxing and drying

- Immersion in the zinc bath during which the galvanized coating is formed

- Passivation according to customer specifications

Control of process parameters

The galvanizing sites of the ZINQ group continuously follow the various parameters of the surface preparation process to optimize the quality of the galvanization. Every week, the different baths are analysed by the group’s chemical analysis laboratory (ZINQ Technologie France).

1. SURFACE PREPARATION

The objective of the surface preparation is to allow the metallurgical reaction between steel and zinc.

Degreasing

This first stage of chemical treatment consists in eliminating the grease and dirt which prevent contact of the subsequent etching solutions on the surface of the pieces.

Stripping

Chemical stripping removes rust and scale (iron oxides) to clean the surface of the part in preparation for the iron / zinc reaction. The acid contained in this bath reacts with the oxides to transform them into soluble salts.

Rinsing

Rinsing is intended to limit the pollution of the flux by transfer of liquid from bath to another.

Fluxing

The fluxing operation has a triple function in the treatment of parts to be galvanized:

- ensures the wettability of the surface

- promotes the metallurgical reaction between iron and zinc during the immersion of the piece

- prevents reoxidation of the part before entering the zinc bath

Drying

The last operation of the surface preparation chain, drying is a necessary step before the complete immersion of the part in the zinc bath. It avoids explosions due to the instantaneous vaporization of the water during the immersion in the zinc bath and by extension to avoid any projections of liquid zinc. It also reduces heat shock during immersion in the zinc bath and thus minimize the risk of deformation of the parts during the galvanizing process.

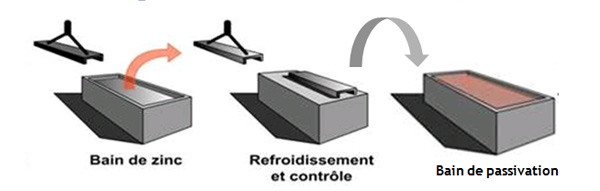

2. Galvanization

ISO 1461 hot dip galvanizing corresponds to the immersion phase of the part in the zinc bath. Depending on the type of part (dimensions, coating thickness…), the immersion time of the piece can vary from 3 to 15 minutes on average. An intermetallic layer is then formed between the steel and the molten zinc, allowing excellent adhesion of the coating.

In addition, in case of accidental coating injury, galvanization provides cathodic protection of the steel, see diagram opposite.

3. Passivation

This involves covering the parts with a protective film in order to prolong the brightness of the galvanization. To do this, the parts are first cooled a few moments after their exit from the zinc bath and then immersed in a passivation bath. This passivation service is currently available in several factories of the ZINQ group.

To learn more about passivation, click here.

CHOOSE A PLANT